Troughs

Mid West Concrete has been manufacturing stock water troughs since 1985. Started originally by Max Osborne in his garage, the business has grown to service clients all over New South Wales and Victoria.

Our troughs are recognised across the industry for being the leaders in innovation and design. How did Max design the first and all subsequent troughs? Simple - he talked to the people that connect them, maintain them, buy them and manage the stock that use them. Good idea right?! Ask your neighbour what they like about our troughs - chances are they have one, or know someone who does.

Our troughs incorporate design innovations that make them strong, durable, cattle ‘damage’-resistant, simple to set up and simple to clean - and this is just the start.

We are constantly working on the quality of our finished product and the raw materials that go into it. We strive to make our sales process the best and simplest. We aim to provide the best delivery schedules with the most helpful drivers. Let us know what you think - we believe all feedback is good feedback.

We invite you to check out our range.

Small animal troughs

Horse troughs

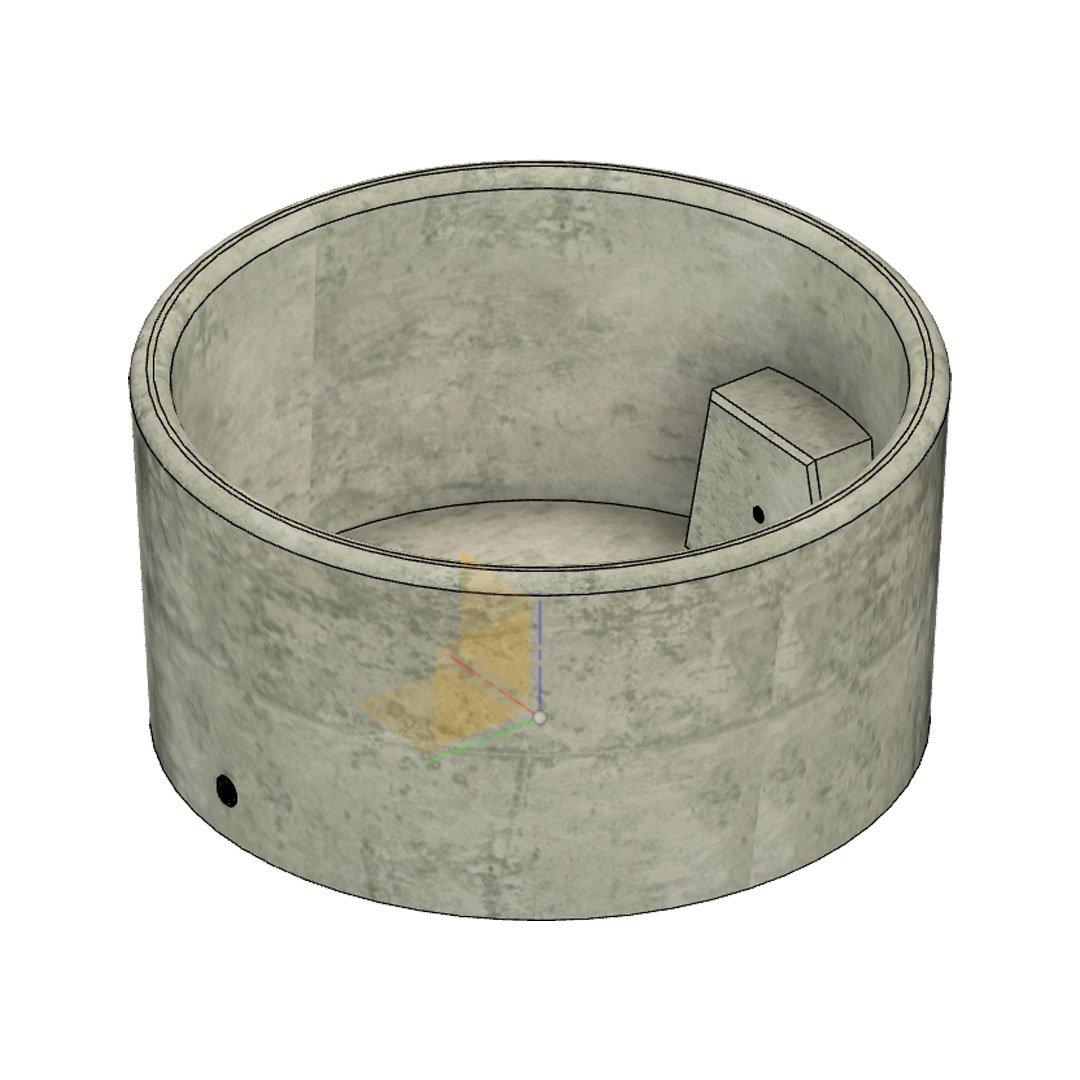

Round troughs

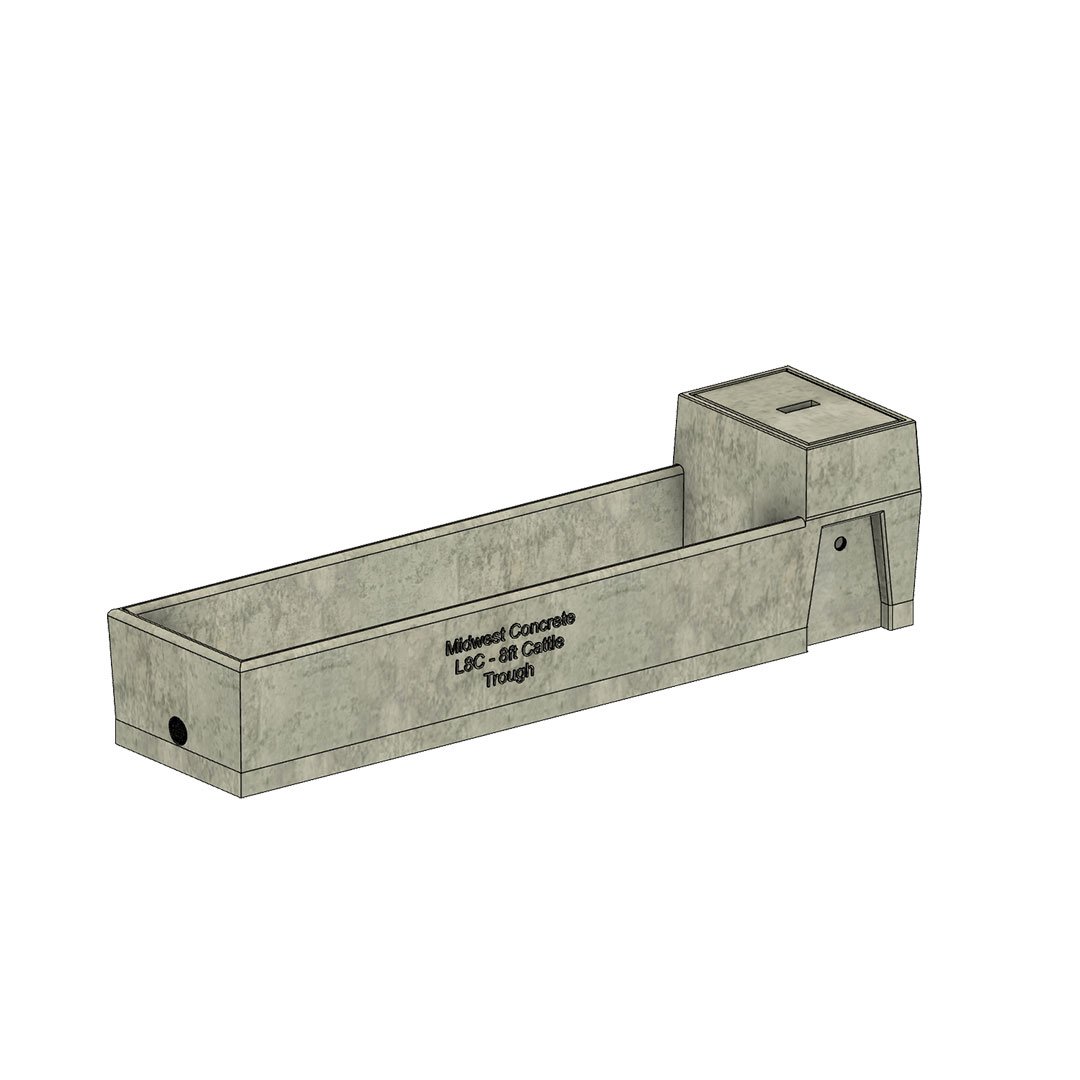

8ft single cell

16ft double cell

16ft single cell – the “longline”

Covered float boxes and auxiliary float cover options

The trough range is standard with brass cast-in inlet and drain fittings. We find these give the best durability and hassle-free performance.

Our valves are a cast stainless steel manufactured just for us to our high standards of durability, serviceability and performance. We are happy to recommend the best valve for your application - simply give us a call to discuss.

Mid West Concrete troughs are made using Australian standard mesh and bar reinforcing. In some instances, we will use corrosion resistant fibre additives to achieve a desired strength specification.

As standard, our concrete products are made with 40MPa concrete in our own design moulds. We use environmentally friendly release agents and have regular testing conducted on our concrete to ensure we exceed our target strengths.

Our troughs - keeping you ahead of the herd!

Stock-proof float cover

Our float box lids are cast concrete and fibre reinforced.

Stop your stock from dislodging covers and damaging valves! This can cause the trough to overflow and waste thousands of litres of precious water, or worse - stop the water and cause stock losses.

Concrete manufacture

Concrete has been used for centuries in situations where we need long-life and durability. Do it once and do it right with concrete.

Deep

Depth of troughs is important. Go the deepest you can for your stock and layout. Deeper water stays cooler in hot weather and is less likely to freeze in cold weather.

Heavy-duty design

Our designs are heavy-duty. Stock yards, paddocks and feedlots are all tough places for any product to survive. Add to this cattle (or any livestock) walking in or over your troughs and you can see what happens to lightweight designs. Built to last - and we back it!

40MPa concrete

40MPa concrete - the standard for industrial concrete manufacture. Don’t accept anything less and ensure you ask for the test certificates.

AS steel reinforced

Steel reinforced with AS/NZS 4671 Steel. Mesh, bar and custom-made ligatures are incorporated into our products. In some situations, we will incorporate reinforcing fibre too. This is non metallic/corrosion-proof and engineered for specific applications.

Smooth finish

We strive for the highest quality finish possible. Our QMS practices such as mould cleaning, specialised organic and water-based release agents, consolidation and controlled curing all aid the process. Sometimes you will see unavoidable surface defects. These are not detrimental to the product and are only skin deep, most often caused by a little too much release agent.

Brass fittings

Our bung housing and valve collar are cast in brass parts. Because of this we get great corrosion resistance and adherence to the concrete during casting.

Free-standing - heavy

Our troughs are heavy! Generally around a tonne each for an 8-footer. This is a good thing because cattle are heavy too and they like to push, lean on and generally make life pretty hard for a trough. Go heavy - they last!

Float box inbuilt into trough body

Our float boxes are built into the rectangle troughs. We do this to stop them from being dislodged or tipped off. If you don’t like this, go with a round trough and choose the optional float cover. Still heavy-duty, but the option is yours.